A person daily encounters glass products. Glass is an almost magical object - on the one hand transparent, on the other a material object. But for some reason, not everyone comes up with the thought - how and what is glass made of? How is the process going?

Interesting Facts:

- It takes a million years for the glass to decompose.

- Glass is recycled without loss of quality.

- The thickest glass in the world is the 26 cm screen of the Sydney aquarium.

What is glass made of?

For the manufacture of glass, craftsmen take: quartz sand (the main component); lime; soda;

How to make glass?

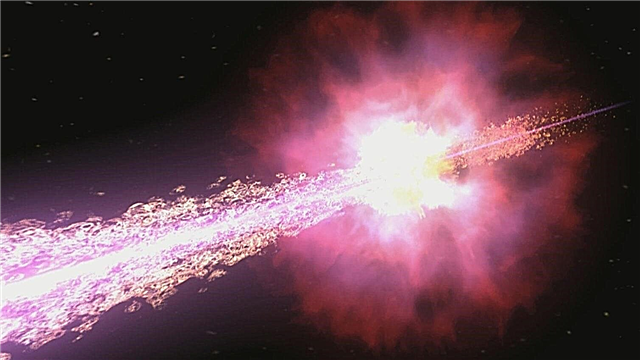

Initially, quartz sand, soda and lime are heated in a special furnace to a temperature of 1700 degrees above zero. The grains of sand are joined together, after homogenized (converted into a homogeneous substance), the gas is removed. The mass is “dipped” into molten tin with a temperature above 1000 degrees, which floats on the surface due to its lower density. The smaller the mass that enters the bathtub with tin, the thinner the glass at the exit.

The finishing touch is gradual cooling. The substance is placed in a special conveyor, where it is cooled to a temperature of 250 degrees above zero. Why transparent glass can be read here.

Interesting Facts:

- The most expensive in the world is Murano glass. Products from it cost millions of dollars. Venice since ancient times was famous for the manufacture of quality glass.It is reliably known that in the XIII century the state government transferred production to the large island of Murano, and the craftsmen were strictly forbidden to leave it. Punishment is a death sentence. In addition, for tourists or other residents of Venice, the entrance to the island was also closed. Such tough measures allowed to keep production secret.

- One of the most interesting mental illnesses of the Middle Ages is the “glass disease”. A person with such a disorder thought that it was made of glass, and was afraid to break. Such an affliction suffered the French king Charles VI. The monarch always wore several layers of clothing and forbade him to touch.

What are the functions of soda and lime in the production process?

Soda helps to reduce the melting point by 2 times. If you do not add it, the sand will be very difficult to melt, and accordingly - to connect individual grains of sand to each other. Lime is needed so that the mass can endure water. If it were not in the composition, the window, for example, would have dissolved immediately after the first rain, and the glass would burst after contact with water.

Interesting Facts:

- China has not produced glass for more than 500 years, from the fourteenth to the nineteenth centuries. Now the state is one of the leaders in production, and controls a third of the global glass market.

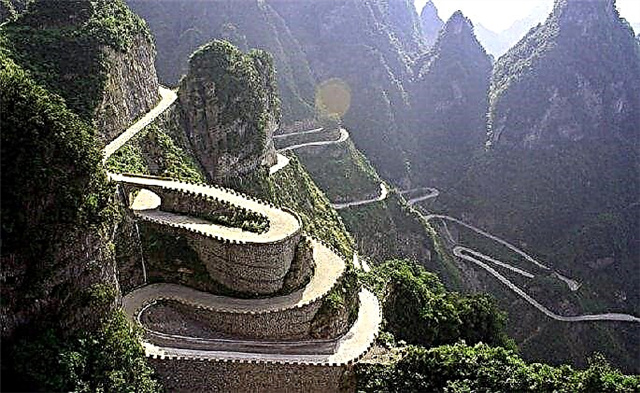

- The year 1994 was extremely active in terms of glass processing in the United States. If you put in one line all the glass products processed during that year, you get a kind of "road" to the moon.

How is colored glass produced?

Glass is not only colorless.To obtain a color product, in addition to the main components, chemical compounds are added to the melting furnace:

- Iron oxides give the glass a rich red tint.

- Nickel oxides - brown, purple (depending on quantity).

- To get a bright yellow hue, add uranium oxides to the sand, soda and lime.

- Chrome makes glass green.

What are the characteristics and properties of glass?

The proportions of the components for the manufacture of glass products are selected depending on their purpose. Allocate: household glass - from which afterwards make dishes, glasses, jewelry; construction - showcases, windows, stained-glass windows;

Technical glass is the most dense. Used in heavy industry. The main property of glass is the “ability” to transmit sunlight through itself. But not completely. So, standard window glass transmits only 85% of sunlight. Glass has low thermal conductivity, simply put - it does not get too hot from other products. This property is widely used for the use of glass in fireplaces (household appliances - stoves and ovens).

Interesting fact: Everyone has heard about armored (bulletproof) glass. The process of its production looks like this: several glass layers are interconnected, fixed with polymer films and sent to the furnace. The first bulletproof glass was installed on the windows of the White House in 1941.

Glass is an amazing material. The process of its creation is complex and traumatic, but interesting and very necessary.